Failure Analysis Laboratory In Mumbai-MTS-India

Have you ever wondered what failure analysis is and why it is important for businesses? Failure analysis is a process of determining the root cause of a component failure or failure of a system. At MTS-India, we offer a specialized Failure Analysis Laboratory in Mumbai, India. Our team of experts provides complete failure analysis metallurgy, including failure mode and effects analysis (FMEA). Here, we will discuss the importance of failure analysis lab and how MTS-India’s team of experts can help you determine the root cause of a component or system failure. We will also discuss the importance of metallurgical testing laboratory services for failure analysis.

What Is Failure Analysis?

Failure analysis is an important process that businesses should consider when planning their operations. Metal failure analysis lab helps to identify and correct mistakes, abnormalities, or failures in the design or manufacturing of products. By doing this, businesses can avoid costly damages and ensure the highest quality products possible.

There are several processes involved in failure analysis, including detective work, data collection, and analysis, fault isolation and diagnosis, development and implementation of a corrective action plan, post-failure reviews/audits/inspections, etc. A failure analysis laboratory can be a valuable asset for businesses because it can help to expedite the process of identifying and correcting failures.

The many applications of failure analysis are vast and varied. For example, a business could use failure analysis to prevent product recalls or to determine the cause of customer complaints. In addition, failure testing can help companies improve their marketing efforts by identifying potential problems with their product launch plans.

Failure testing is an important step in ensuring the long-term success of any business. With the help of a qualified Failure Analysis Laboratory like MTS India Ltd., your business can overcome any challenges that may arise during operation. Contact us today to learn more!

Analyzing Failures To Find The Root Cause

Failures are inevitable and part of the learning process for any business. However, understanding and analyzing failures can reduce their overall cost and risk. A Failure Analysis Lab provides businesses with several important benefits, including improved product reliability, faster problem identification and resolution, and greater knowledge of customer needs.

At a Failure Analysis Lab, major services include:

- Material testing.

- Quality control inspections.

- Data collection and analysis.

- Technical expertise & experience is available for analysis.

In addition to these core services, labs may offer specialized electrical or mechanical testing services.

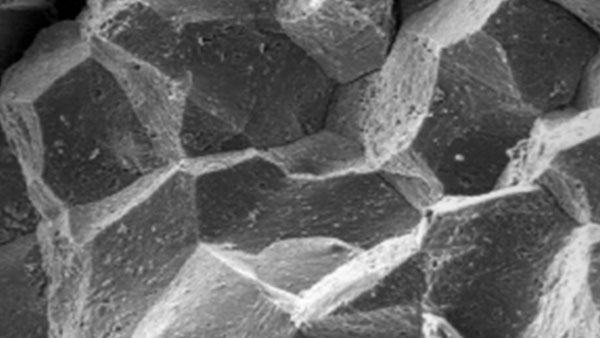

The types of materials tested at a lab depend on the business’s specific needs. Tests include Corrosion testing and investigation, Heat treatment services, Microstructure analysis , etc.

Quality control regulations are followed closely at all Failure Analysis Labs to maintain consistent standards across all test results. This helps to ensure that data is accurate and reliable when analyzed by technical experts & experienced analysts.

Data is collected from various sources throughout the failure analysis process to build a comprehensive picture of what happened and how it could be prevented in the future

Best practices for identifying root causes of failure are learned through experience & repeated successes or failures。 These best practices’ effectiveness is constantly evaluated to make necessary updates or changes.

Following proper guidelines when conducting failure analysis ensures that your business remains resilient against potential setbacks caused by failed products or defective processes.

MTS-India’s Failure Analysis Services

Failure analysis is an essential step in the process of product development. It helps to ensure that products meet the required standards and are free from defects. MTS-India provides a wide range of quality assurance services, including advanced laboratory testing, digital solutions, and specialist engineers with experience in failure analysis.

The most important aspect of quality assurance is ensuring that all tests are performed correctly. With MTS-India’s experienced and skillful experts in metal failure analysis, you can be confident that your products will meet all standard requirements. Additionally, our Quality management system ensures that all processes are followed correctly to ensure superior customer service and high product reliability.

In addition to ensuring product reliability, failure analysis can also provide valuable insights into how customers use products and help to improve design features for future iterations of a product line. With MTS-India’s comprehensive failure reports, you’ll have everything you need to make informed decisions about future product development. And since we offer 24*7 support for our customers, there’s always someone available when you need them!

The Comprehensive Solutions For Failure Analysis In Mumbai

Failure analysis is an important part of any manufacturing process. It helps to identify and correct potential problems before they cause damage or lead to failure. Our Mumbai failure analysis center offers a wide range of services to avoid these problems.

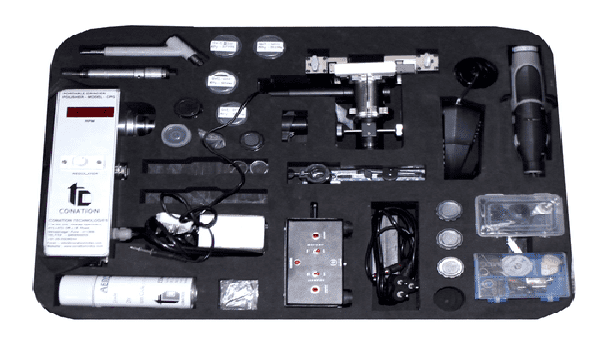

Our team of experts can provide a complete analysis of metals and alloys, failure investigation services, wear and tear assessment, stress analysis and inspections, and more. We also have the expertise and equipment to carry out advanced metallographic analysis, laser scanning microscopy, non-destructive testing services, specialized failure analysis reports, and more. Our mission is to help you prevent failures from happening in the first place – let us help you achieve this goal.

Failure Mode And Effects Analysis

FMEA is a process that helps to identify and analyze the possible problems that could occur during a system’s design, manufacture, or operation. Doing this can prevent potentially harmful consequences and improve your business processes’ overall reliability.

Below, we will outline some of the benefits of FMEA in improving business processes. First, FMEA can help to identify potential problems early on in the process – before they become too costly to fix. This means you can avoid costly mistakes and save valuable time and resources. Also, FMEA can help ensure that your products are designed for safety and durability in even the worst circumstances

To use FMEA effectively, you will need to gather important data about your system. This data may include information about your product design, manufacturing processes, user requirements, etc. Once this data is assembled, it is time to perform failure mode and effect analysis (FMEA) techniques.

The main documents involved in FMEA include a risk assessment report (RAR), failure modes and effects profile (FMP), critical paths chart (CPC), cause-and-effect matrix (CEM), vulnerability assessment report (VAR), risk rating table (RRT), etc. Each document plays an important role in helping you understand the risks associated with your system design. Furthermore, by using Failure Analysis Laboratory services in Mumbai Mts India, you can ensure that all your FMEA documentation is accurate and up-to-date.

Finally, metal failure analysis is not always easy or enjoyable, but it is essential to any quality assurance program. Identifying potential problems early in the process can significantly reduce project risks, leading to improved business processes.

Evaluating Potential Failures In Laboratory

Failure Analysis is an important process that businesses use to ensure that their products and services are safe for consumers. Businesses need a reliable failure analysis lab with proper equipment and technology to evaluate potential failures. At MTS India, we have years of experience conducting failure analysis and have developed a reputation for providing quality results.

The most important factor in the success of a failure analysis lab is proper equipment. A lab with outdated or inaccurate equipment can lead to inaccurate results, which can be disastrous for businesses. At MTS India, we always ensure that our equipment is up-to-date and accurate so that you can trust our findings.

Another key factor in the success of a failure analysis lab is experienced personnel. A team of professionals who are knowledgeable about failure analysis will be able to provide you with accurate results quickly and efficiently. This will help you avoid costly mistakes and keep your products safe for consumers.

In addition to providing quality results, a comprehensive failure analysis plan has many benefits. By having a plan, you can minimize the risk of product failures by anticipating them and taking appropriate action to prevent them from happening in the first place. This will save you time and money down the road!

Finally, one of the reasons why MTS India is such a popular choice for Failure Analysis laboratories is that we offer affordable rates without sacrificing quality or accuracy. We believe everyone should have access to fail-safe products without sacrificing their budget – which is why we offer such low rates without compromising on quality or service.

Why Do You Need Failure Analysis?

When something goes wrong with a product or service, it can lead to a lot of inconvenience for the customer and cost for the company. Failure Analysis is key to ensuring that products and services meet customer expectations and are reliable. By understanding the cause of problems, you can help to prevent them from happening again and suggest corrective action.

Failure Analysis begins by understanding the cause of problems and irregularities in services or products. This information can be used to identify reliability concerns within products or services. After that, you can analyze materials associated with product or service failure to determine the cause of failure. Finally, you will help define procedures that must be followed when dealing with product or service failure – ensuring that all steps are taken to prevent it from happening again.

In short, Failure Analysis lab helps companies reduce costs associated with rework, repairs, and replacements due to product or service failures. It also helps ensure customer satisfaction by isolating reliability concerns early in the process. By doing this, you improve your products and reduce the risk of future problems down the road.

Understanding Failure Mechanics For Quality Control

Quality control is an important part of any manufacturing process, and the quality of your products must be maintained throughout the entire process. As Metallurgical Testing Laboratory Services in Mumbai, our team understands this importance and is committed to providing quality services that help you ensure product standards and good manufacturing practices.

One way that we help to ensure product quality is by analyzing and reporting on failure mechanisms. By understanding what causes failures in your products, you can prevent them from happening in the future. This knowledge also helps you to troubleshoot on-site problems quickly and efficiently. Additionally, we have access to a wide range of advanced lab equipment and facilities that allow us to perform non-destructive testing methods such as X-ray diffraction or microanalysis. This allows us to determine the cause of failures even when they are difficult or impossible to see.

In addition to our quality control services, we also offer Verification of Process Capability and Effectiveness (VPCE) services. This service helps you assess whether your processes are capable of producing the desired results or not. It also verifies whether your processes are effective at meeting customer needs. Using this service, you can ensure that your products meet all necessary standards before leaving your facility.

Finally, one of our main goals is always to develop standards that improve quality control throughout the manufacturing process. Doing so can reduce the chance of future failures and uphold high standards for all of your products.