Failure Analysis Laboratory In Kolkata-MTS-India

When it comes to metal failure analysis, it is important to ensure you use the best possible laboratory for the job. That is why you should consider using the Failure Analysis Lab from MTS-India. MTS-India is a metallurgical testing laboratory services located in Kolkata, India, and is renowned for its expertise in failure analysis metallurgy. Here will discuss failure analysis, the benefits of using a failure analysis laboratory, what MTS-India offers, and why you should choose MTS-India for your laboratory needs. End of this post, you will have all the information you need to make an informed decision about your metal failure analysis laboratory.

What Is Failure Analysis?

Failures are inevitable in any business or service. However, properly analyzing and preventing failures can greatly impact your business. Failure Analysis is the process of analyzing failures and learning from them so they can be avoided in the future. Failure Analysis has many benefits for businesses and service providers, including increased efficiency, improved customer service, and more.

To understand failure Analysis better, it’s helpful to have a definition of it first. Failure analysis is the process of identifying failures and their causes within a system or process. It helps to identify weak points in a system so they can be fixed before they cause serious problems. Failure testing also helps discover solutions to problems that have already occurred. By fully understanding how failures happen and what can be done to prevent them, businesses can take the necessary steps to stay afloat and competitive.

When it comes to choosing an appropriate failure analysis laboratory in Kolkata Mts India, there are many factors that you need to consider. First and foremost, you’ll want to ensure that the laboratory has experience performing failure cause analysis procedures correctly. Next, you’ll want the laboratory to have the proper tools and resources necessary for performing failure analysis work effectively. Last but not least is the price.

Assuming everything looks good on paper (or online), some preparations still need to be made before starting actual work on a project. For example, following proper Failure Analysis protocols is essential for ensuring accurate data collection during investigations into failed systems. Protocols typically include establishing baseline data measurements before any changes take place within a system、identifying abnormal patterns、and measuring post-change performance。 Once all pre-failure preparations have been completed、the actual Failure Analysis Work begins! This blog will discuss different types of Failures analysis Laboratories based on location, such as Kolkata Mts India, which offers great advantages like faster turnaround time, etc.

The Benefits Of Using A Failure Analysis Lab

Working in a failure analysis lab can be a great way to ensure that your products are reliable and free from defects. By using microscopic and radiographic inspections, you can identify the root causes of failures and determine if a part has been manufactured correctly or is defective. You can also identify mechanical damage and wear patterns, analyze materials’ chemical composition and structure, analyze structural integrity, and trace the source of defects. In addition to these standard techniques, you can use various cutting-edge equipment to speed up the failure analysis.

Understanding the root causes of failures and using the right tools can help your business avoid costly mistakes. Streamline data collection by gathering information in a centralized location, and get customized reports on failure analysis results in less time than ever before. Utilize a wide array of failure analysis techniques to provide complete insight into your product’s condition – from microstructural damage to material strength. With this information at your fingertips, you’ll be able to prevent failures from happening in the first place or take quick action when they occur.

Understanding The Basics Of Failure Analysis Testing

Failure Analysis Testing is a process used to identify and correct problems before they cause a system or artifact to fail. Failure Analysis Testing is important because it helps ensure systems and artifacts’ reliability. By understanding the basics of Failure Analysis Testing, you will better understand why it is important and how it can be used by organizations.

What is Failure Analysis testing?

Failure Analysis Testing (FAT) is a systematic approach for identifying, diagnosing and correcting failures before they cause system or artifact failure. FAT helps organizations to achieve reliability goals by identifying and correcting problems before they cause system or artifact failures. FAT identifies potential failures through tests and analysis of test results. It can be applied in various industries, such as software development, systems engineering, information technology management, operations research, etc.

Applications of Failure Analysis Testing?

Failure analysis testing can be used differently depending on the application area and business needs. Some common application areas include software development, systems engineering, information technology management, operations research, etc. In each application area, there are specific uses for failure analysis testing, which are described below.

Software Development:

– FIT assists in the early detection of bugs during software development by providing an early view into product quality attributes such as reliability (scope), timeliness (frequency), completeness (metadata), etc. It also aids in debugging software by finding errors earlier, which reduces the overall cost of fixing errors late during software development life cycle phases like beta/RC/production release cycles.

– FIT also assists in modifying existing software products without causing any data loss or data inconsistency between releases, thereby improving the end-user experience. FIT identifies potential regressions caused by code changes before release, aiding developers during code reviews. FIT also enhances team collaboration through effective communication among development team members responsible for simultaneously developing different parts of the product. Thus, FIT plays an important role across software delivery life cycle phases like requirements gathering, design, coding, testing, packaging, installation, etc.

Systems Engineering:

– FIT helps with fault identification during the early design phase, helping prevent costly rework later on due to undetected faults at earlier stages while helping with accurate risk estimation associated with future modifications/upgrades, etc. Systematic identification of faults at various design levels helps identify opportunities for economizing while meeting system availability and integrity requirements.

Operations Research:

– FIT facilitates efficient decision-making under uncertainty using experimental data generated from real-world operational incidents.

What Does MTS-India Offer?

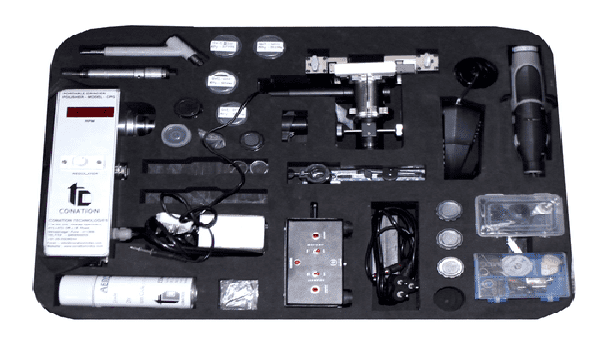

When it comes to manufacturing and execution of processes, it’s essential to have a team of experts who can help identify and correct potential problems before they cause serious damage. That’s where MTS-India comes in. Our high-tech failure analysis laboratories are equipped with the latest technologies and techniques for diagnosing and analyzing failures in industrial manufacturing processes. By providing comprehensive testing services for metallurgical and welding components, we can optimize critical business needs and reduce risks associated with production.

Our team of skilled professionals comprises experts in metal failure analysis, metallurgy, welding, process engineering, quality assurance, and more. We have years of experience working with the latest technologies in industrial manufacturing, which gives us access to the most advanced techniques for detecting failures. Our clients can be confident that we’ll provide them with tailored solutions that meet their needs. And to ensure the accuracy and reliability of our results, we adhere to strict quality assurance protocols. So if you’re looking for an experienced team with a deep knowledge of industrial manufacturing processes – look no further than MTS-India!

Specialist Failure Analysis Testing Services From MTS-India

Failure testing is inevitable, but it doesn’t have to be costly or inconvenient. MTS-India specializes in providing comprehensive failure analysis services in Kolkata. Our team of highly qualified technical experts is experts in analyzing failed parts, and we have onsite lab facilities with the latest testing and analytical equipment. We also offer expert guidance on material selection and operation of machinery so that you can solve your failure problems quickly and at a low cost.

We have various failure testing services, including mechanical, thermal, electrical, chemical, and more. So whether you need help with complex failures or need a quick solution for a simple problem, MTS-India has you covered. We also offer 24/7 response time and support from our team of experts. So don’t hesitate to contact us today for all your specialist failure analysis needs!

Metallurgical Testing Services India’s Methodology And Expertise

Metallurgical Testing Services India has over a decade of experience in metallurgical testing and analysis. Our methodology and expertise are unparalleled in the Indian market, and we can provide you with the necessary information to ensure that your products meet all specifications.

Our bulk metallurgical testing services include analysis of alloys and failed components, characterization of alloys and metals, further investigations utilizing microstructural studies and fractography, advanced failure analysis capability, qualitative and quantitative analysis for certifications, complete non-destructive analysis (CNA), specialized report writing services, technical consulting support, as well as customized test methodologies for special projects.

We understand the importance of quickly providing our clients with accurate results–whether for certification purposes or to ensure that your products are up to spec. That’s why we offer 24/7 customer support via phone or email. We also have a team of experienced technical writers who can help you create high-quality reports without prior experience in metallurgy or engineering.

If you’re looking for quality metallurgical testing services at an affordable price, look no further than Metallurgical Testing Services India!

Strength Through Metallurgical Examinations And Analysis

If you’re manufacturing or processing materials, you need to have a comprehensive failure analysis program in place. Comprehensive failure analyses are essential for ensuring that your products and customers are safe. Not only does this analysis provide you with detailed diagnostic reports, but it also helps to identify problems early and address them before they become serious.

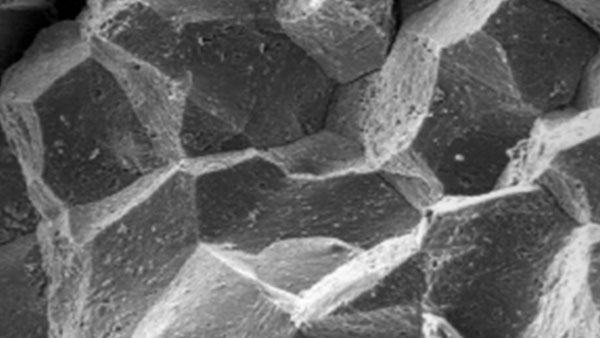

At our facility, we have years of experience in a wide range of matting and material testing. We’re experts at quickly assessing failure cause analysis and providing rapid turnaround times for urgent cases. In addition to our expertise in metals and materials, we utilize advanced technologies like scanning electron microscopes and spectrophotometers to understand the failures.

We serve industries ranging from aerospace to automotive to medical devices and food processing. Our cost-effective programs lay the groundwork for effective quality control, so you can be confident that your products will meet customer specifications. And if you ever have any questions or concerns, our team is here to help you day or night!

Why Choose MTS-India For Your Lab Needs?

We are looking for a quality lab that offers competitive prices and top-quality services. Look no further than MTS-India! Our team of highly qualified experts has years of experience in failure analysis, and we are experts in metallographic testing. We use the latest technology to help us get the most accurate results, and our reports are based on our experiments. We also offer comprehensive solutions for field testing and inspection woes. Whether you need help with lab tests or need guidance on how to run them correctly, we’re here to help. Also provide mechanical testing services, microstructural analysis, heat treatment services, corrosion testing laboratory services , and more.

We understand that you may have many questions about lab testing, so we offer 24/7 support to answer all your queries. In addition, we comply with national and international quality control standards to ensure that your results are always accurate. Contact us today for all your laboratory needs!

Leveraging MTS-India’s Expertise For Quality Lab Testing And Analysis

Quality is key in any business, and that includes the failure testing and analysis of metal products. That’s why having a reliable failure analysis laboratory like MTS India on your team is important. MTS India’s Failure Analysis Laboratory is equipped with the latest technology and equipment, so you can trust that your products will be analyzed correctly.

Inside the lab, you’ll find state-of-the-art testing equipment for various metals. This includes testing for hardness, wearability, malleability, ductility, corrosion resistance, and other properties. In addition to metal testing, MTS India’s laboratory also offers services for plastic materials and composites. If you need product testing or quality assurance assistance, MTS India has a team of experts dedicated to providing quality service at a reasonable price.

MTS India offers outsourcing services from its laboratory to ensure that your products are delivered to international clients in the best possible condition. This allows you to outsource some of the more tedious or time-consuming tasks while maintaining full control over the quality of your products. With decades of experience in metal testing and evaluation, MTS India is an invaluable resource for quality lab tests and analysis services.

Reaping The Benefits Of Metallurgical Testing Results With Experienced Technicians At Kolkata’s Failure Analysis Laboratory

At Kolkata’s Failure Analysis Lab, we offer a wide range of services that can help you improve your product reliability. We specialize in metallurgical testing, which is the process of testing metals’ physical and mechanical properties. By providing accurate and cost-effective metallurgical testing results, we can help you identify problems early on and prevent them from causing failures.

Below, we will outline some benefits you can enjoy working with FAL Kolkata. First, our experienced technicians are skilled in providing accurate metallurgical testing results. This means that you can trust our lab to provide reliable information to help you make informed decisions about your product.

Second, metallurgical testing laboratory services is an efficient way to find defects in your products before they cause any problems. Using this technology early in product development can save you time and money. In addition, by identifying potential problems with your products early on, you can ensure that they meet required safety and reliability standards.

Last but not least, by using metallurgical testing results from FAL Kolkata, you can improve the quality and accuracy of your metallurgical test data. This makes it easier for you to understand how your products perform under different conditions and helps ensure better overall manufacturing processes. Finally, we’d like to share real-world examples of how our laboratory has helped companies succeed with their metal products. Thanks for reading!