Service

In-Situ Metallography and Replica Extraction

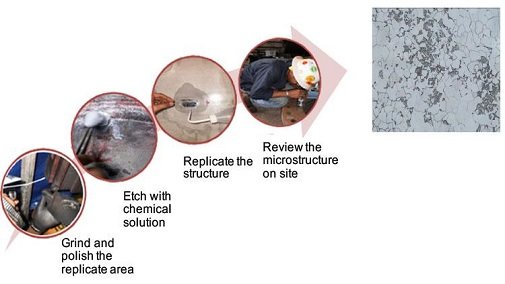

As an NDE method, Field metallography is widely used for microstructure analysis on large structures that cannot be easily moved or destructive sample preparation is difficult or not permissible, such as storage tanks, piping system or drilling rigs. In-situ Metallography allows for quick on-site evaluation of a component’s metallurgical and heat treatment condition. Grain size and grain flow, carbides, cracks and undesired phases can be readily identified. MTS deputes a senior metallurgist to carry out In-Situ/Field Metallography.

MTS failure analysis laboratory works to determine the cause of a failure and provide the customer with insight for solving the problem. Forensic investigation, engineering, and failure analysis expertise are available for a wide range of products and materials, using an extensive range of proven techniques and applications.

In situ Metallography helps in remaining life assessment study or failure analysis. The normal procedure is as follows: portable grinder and polisher are used for on-site sample preparation. Then a field microscope is used to examine the quality of the polish. After a satisfactory finishing is achieved, a compatible chemical etchant is used to reveal the microstructure of the polished spot. If desired, electrochemical etching can also be performed. Finally, digital images can be taken by portable microscope with up to 500x magnification.

If greater resolution is required, MTS specialists can perform field replica service using acetate film or silicone based resin based on ASTM E 1351. Replicas can be viewed and analyzed by optical microscope or scanning electron microscope if higher magnification is needed.

Popular Search : In-Situ Metallography | MTS-India