Service

PMI

Positive Material Identification (PMI) is the analysis of a metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. A handheld XRF PMI gun can analyze, identify and display grade and composition of a material in less than 5 seconds without creating any marks on the material or destroying the sample in any way.

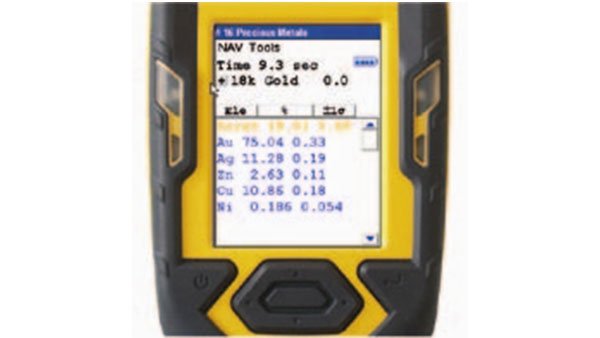

In MTS, PMI testing is done using an analyzer named NITON XL2 800 Series, X-ray fluorescence (XRF) analyzer. NITON XL2 800 Series XRF analyzer offer high performance and advanced electronics while maintaining the point-and-shoot simplicity.

PMI Testing Services – MTS India

MTS India offers advanced PMI Testing (Positive Material Identification) services using state-of-the-art XRF analyzers for fast, accurate, and non-destructive verification of metal alloys. In industries where material integrity, quality, and traceability are critical, PMI Testing helps ensure that the right materials are being used — and that they meet required specifications before, during, or after fabrication.

With extensive experience across sectors such as oil & gas, petrochemical, power, construction, and manufacturing, MTS India’s PMI Testing is your trusted solution for material verification, compliance testing, and quality assurance.

What is PMI Testing?

PMI Testing, or Positive Material Identification, is a non-destructive analytical technique used to determine the elemental composition of metals and alloys. It is widely used for verifying material grade, confirming chemical composition, detecting mix-ups, and ensuring compliance with engineering standards.

MTS India uses the NITON XL2 800 Series X-ray fluorescence (XRF) analyzer, a high-performance handheld device that delivers rapid and reliable results — typically within 5 seconds — without altering or damaging the tested sample.

Key Features of MTS India’s PMI Testing

✅ Non-Destructive and Instant Results

PMI Testing at MTS is done using XRF technology that leaves no marks or damage on the sample, making it ideal for in-service parts and critical components.

✅ High Accuracy and Precision

Our NITON XL2 800 Series analyzer offers high-resolution elemental analysis, capable of detecting a wide range of elements from heavy metals to light alloys with superior accuracy.

✅ Field and Lab Testing

We offer both on-site PMI Testing for real-time verification and in-lab testing for detailed analysis, giving you complete flexibility based on your project needs.

✅ Portable, Easy-to-Use Equipment

The handheld nature of our PMI analyzer allows access to hard-to-reach or complex geometries without needing to remove components from service.

Applications of PMI Testing

PMI Testing plays a vital role in various industrial applications where material mix-ups can lead to catastrophic failures or regulatory issues:

1. Incoming Material Inspection

Verify the grade and composition of raw materials, pipes, plates, or fittings before they enter your production line. Prevent costly mistakes and ensure supplier compliance.

2. In-Process Verification

Ensure the correct materials are used during fabrication, welding, or assembly. Confirm grade changes or heat numbers to avoid mix-ups.

3. Weld Verification

Check the base material and filler metal composition in welds to confirm consistency and compliance with welding procedures and standards.

4. Failure Investigation

When a component fails, PMI Testing can reveal whether incorrect material was a contributing factor, providing crucial evidence in root cause analysis.

5. Plant Maintenance and Shutdowns

In oil, gas, chemical, and power plants, PMI is routinely used during shutdowns to identify unknown materials in service, helping guide repair or replacement plans.

What Can Be Detected with PMI Testing?

Using PMI Testing, MTS India can detect and quantify various elements including:

- Iron (Fe)

- Chromium (Cr)

- Nickel (Ni)

- Molybdenum (Mo)

- Copper (Cu)

- Cobalt (Co)

- Titanium (Ti)

- Vanadium (V)

- Zinc (Zn)

- Lead (Pb)

- Aluminum (Al)

- Silicon (Si)

- Manganese (Mn)

This allows for accurate identification of materials such as stainless steels (304, 316, etc.), high-temperature alloys, nickel alloys, aluminum alloys, duplex steels, and more.

Benefits of MTS India’s PMI Testing Services

🔍 Quick Material Confirmation

With instant results, PMI Testing speeds up inspection, verification, and certification processes, especially in fast-paced industrial settings.

🧰 Minimal Downtime

On-site testing reduces downtime during plant turnarounds, shutdowns, or commissioning, helping you meet tight schedules.

🛡️ Safety and Compliance

Avoid catastrophic failures and regulatory violations by ensuring that only certified materials are used in pressure vessels, pipelines, and structural applications.

💰 Cost Efficiency

Prevent costly repairs, reworks, or liability claims by verifying material grades before installation or welding.

📄 Detailed Reporting

MTS provides comprehensive reports detailing the grade, elemental composition, instrument calibration, and testing conditions for full documentation and traceability.

Why Choose MTS India for PMI Testing?

At MTS India, we don’t just provide equipment-based testing — we deliver expert-backed material verification that integrates seamlessly into your quality assurance programs.

✅ Expertise That Matters

Our metallurgists and materials engineers bring deep experience in industrial metal testing and failure prevention, helping you interpret results with confidence.

✅ Certified and Calibrated Equipment

We use the NITON XL2 800 Series XRF analyzer, known for its high accuracy, fast processing, and rugged design, calibrated regularly to ensure valid results.

✅ Flexible Deployment

Whether it’s a small batch inspection in our lab or a large-scale audit across a plant site, we scale our PMI Testing services to meet your operational scope.

✅ Safety and Compliance Focused

All testing is conducted in accordance with safety regulations and ASTM/ISO standards, ensuring compliance with industry norms.

Industries We Serve

MTS India’s PMI Testing services support a wide range of sectors:

- Oil & Gas – Pipeline, pressure vessels, and valve material verification

- Petrochemical & Chemical Plants – Shutdown inspection, corrosion prevention

- Power Plants – Turbine blades, boiler components, and piping analysis

- Fabrication & Welding – Base material and filler wire verification

- Automotive & Aerospace – Alloy conformity, lightweight material validation

- Construction & Infrastructure – Rebar, fasteners, and structural steel testing

- Pharmaceutical & Food Industries – Stainless steel equipment compliance

PMI Testing in Action – A Case Snapshot

Industry: Petrochemical Refinery

Objective: Material verification during scheduled plant shutdown

Approach: On-site PMI Testing of over 600 pipeline joints and fittings using handheld NITON XL2

Outcome: Detected 4 mismatched components with incorrect chromium and molybdenum content, preventing premature corrosion and unplanned downtime

Benefit: Ensured safety compliance and avoided costly pipeline replacement

FAQs – PMI Testing

Q1. What standards are followed for PMI Testing?

We follow standards such as ASTM E1476, ISO 17025 (for lab practices), and manufacturer equipment guidelines to ensure consistent and accurate testing.

Q2. Can PMI Testing detect carbon?

No. XRF-based PMI Testing cannot detect carbon. For carbon analysis, Optical Emission Spectroscopy (OES) or combustion analysis is required.

Q3. Is PMI suitable for in-service components?

Yes. PMI is non-destructive and safe for live components as it does not affect the structural integrity or performance of the material.

Q4. What sample preparation is needed?

Minimal preparation is required. However, the surface should be clean and free of coatings or corrosion for accurate readings.

Contact MTS India – Trusted Experts in PMI Testing

If you’re looking for fast, reliable, and professional PMI Testing services, look no further than MTS India. Whether for incoming inspection, field verification, or material traceability, we ensure your metals meet the mark — every time.

📞 Call us at +91 98417 07777

📧 Email: info@mts-india.in

🌐 Website: https://mts-india.in/

MTS India – Ensuring Material Confidence Through Advanced PMI Testing.

Popular Search : PMI Testing Lab | PMI Lab | MTS-India