Service

In-Situ Metallography and Replica Extraction

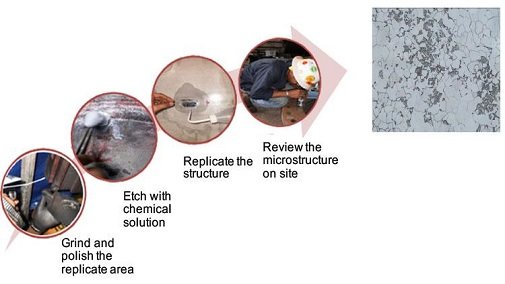

As an NDE method, Field metallography is widely used for microstructure analysis on large structures that cannot be easily moved or destructive sample preparation is difficult or not permissible, such as storage tanks, piping system or drilling rigs. In-situ Metallography allows for quick on-site evaluation of a component’s metallurgical and heat treatment condition. Grain size and grain flow, carbides, cracks and undesired phases can be readily identified. MTS deputes a senior metallurgist to carry out In-Situ/Field Metallography.

MTS failure analysis laboratory works to determine the cause of a failure and provide the customer with insight for solving the problem. Forensic investigation, engineering, and failure analysis expertise are available for a wide range of products and materials, using an extensive range of proven techniques and applications.

In-Situ Metallography and Replica Extraction Services – MTS India

MTS India offers advanced In-Situ Metallography and Replica Extraction services, enabling industries to assess the metallurgical condition of components without removing them from service or causing any damage. As a trusted name in metallurgical testing and failure analysis, we bring laboratory-grade microstructural evaluation to your site, no matter how large or remote the equipment.

In critical industries such as oil & gas, power generation, petrochemical, and heavy engineering, assessing the integrity of in-service components is vital. With our portable equipment and expert metallurgists, MTS India helps you detect issues like heat-affected zones, micro-cracks, phase transformations, and degradation — all without interrupting operations.

What is In-Situ Metallography and Replica Extraction?

In-Situ Metallography and Replica Extraction is a non-destructive examination (NDE) method that allows the evaluation of a material’s microstructure directly at the component site. Also referred to as Field Metallography, this technique is ideal when removing a sample or component for lab analysis is not practical due to size, criticality, or cost.

Replica Extraction involves preparing the surface of the component, polishing it to a mirror finish, etching it, and then capturing its microstructure using a thin acetate or plastic film. This replica is then analyzed under a microscope in the laboratory for deeper microstructural insight.

Why Choose In-Situ Metallography and Replica Extraction?

✅ Non-Destructive and On-Site

No cutting, no downtime. The method is performed without affecting the component’s performance or requiring disassembly.

✅ Microstructural Clarity

Quick detection of issues such as grain coarsening, carbide precipitation, sensitization, creep damage, and other heat-related changes.

✅ Preventive Maintenance Tool

Identify material degradation before it leads to catastrophic failure. This approach is widely used in life assessment of components and in RBI (Risk-Based Inspection) strategies.

✅ Fast, Accurate, and Cost-Efficient

Field metallography allows for quick decisions regarding repairs, replacements, or continued operation without the delay of sample removal and shipment.

Our Methodology at MTS India

At MTS India, we take pride in offering precise and reliable In-Situ Metallography and Replica Extraction services. Our process includes:

1. Initial Evaluation & Planning

Our engineers and metallurgists evaluate the operational and structural context of the component. This helps us choose the right surface preparation technique, etchant, and replica material.

2. Surface Preparation

Using specialized portable grinding and polishing tools, we prepare the component surface to a mirror-like finish. This is done carefully to ensure that the microstructural details are preserved without damaging the base material.

3. Etching

A suitable chemical etchant is applied to reveal the microstructure. The choice of etchant depends on the base metal (carbon steel, stainless steel, alloy steel, etc.) and the expected microstructural features.

4. Replica Extraction

A cellulose acetate or plastic film is pressed against the etched surface to capture the microstructural imprint. The replica is then removed, preserved, and transported to our lab for microscopic examination.

5. Microscopic Analysis & Reporting

At our fully equipped metallurgical laboratory, the replica is analyzed using optical and scanning electron microscopes. We look for:

- Grain size and orientation

- Phase distribution

- Carbide presence and distribution

- Creep voids or early signs of creep damage

- Weld HAZ (Heat-Affected Zone) condition

- Intergranular corrosion or sensitization

A comprehensive report is provided with micrographs, expert interpretation, and actionable recommendations.

Applications of In-Situ Metallography and Replica Extraction

In-Situ Metallography and Replica Extraction is widely used in:

- Remaining Life Assessment (RLA) of boilers, pipelines, and pressure vessels

- Weld inspections, especially in HAZ regions

- Creep damage detection in high-temperature service components

- Failure analysis of in-service structures without dismantling

- Material verification before and after heat treatment

- On-site quality control during fabrication or installation

Common Materials We Analyze

Our metallurgists at MTS India have deep experience with:

- Carbon steels

- Low alloy steels (e.g., Cr-Mo steels)

- Austenitic and ferritic stainless steels

- Duplex steels

- High-temperature alloys (e.g., Inconel, Hastelloy)

- Weld joints and overlays

Each material demands a specific preparation and etching approach, which our experts execute with precision.

Industries We Serve

Our In-Situ Metallography and Replica Extraction services are critical to industries that require continuous operation and cannot afford to remove large components:

- Power Generation – steam headers, turbine casings, boiler tubes

- Oil & Gas – heat exchangers, pipelines, pressure vessels

- Petrochemical & Refineries – reactors, reformers, columns

- Shipbuilding & Marine – propulsion shafts, high-strength steels

- Heavy Engineering – cranes, presses, and load-bearing frames

Wherever there’s a need to evaluate microstructure on-site, MTS India delivers with speed, precision, and expertise.

Why MTS India?

Choosing MTS India means working with one of India’s most trusted names in metallurgical testing and failure analysis. We combine field expertise with lab-grade accuracy to bring you the best of both worlds.

Here’s what makes us stand out:

- 🔬 Trained and certified metallurgists with years of field experience

- 🧪 Portable, state-of-the-art NDE equipment

- 📝 Detailed and defensible reports suitable for audits, insurance, and legal documentation

- ⚙️ End-to-end services — from field evaluation to lab testing to root cause analysis

- 🌐 Nationwide coverage – quick mobilization across India

We work closely with quality control departments, maintenance engineers, and plant managers to deliver clear insights that support smarter decision-making.

FAQs – In-Situ Metallography and Replica Extraction

Q1. Is the component damaged during this test?

No. The method is completely non-destructive. Only light polishing is done, and no material is removed from the component.

Q2. How long does the process take?

Typically, on-site surface preparation and replica extraction take 2–4 hours per location, depending on the accessibility and complexity.

Q3. What resolution does the replica offer?

Replicas can reveal features down to a few microns in size. It’s suitable for analyzing grain structure, phase boundaries, and early creep damage.

Q4. Can this method detect cracks?

It can detect surface-connected micro-cracks and intergranular cracking, especially in creep-damaged or sensitized zones.

Get In Touch with MTS India

Looking for accurate, fast, and reliable In-Situ Metallography and Replica Extraction services in India? Trust MTS India’s metallurgical experts to deliver field-tested results when and where you need them most.

📞 Call us at +91 98417 07777

📧 Email: info@mts-india.in

🌐 Website: https://mts-india.in/

Schedule your field metallography today and prevent tomorrow’s failure.

Popular Search : In-Situ Metallography | MTS-India