Service

Heat Treatment Consultancy

MTS specializes in rapid response to technical and business needs in the Heat Treating Industry. We do our job when and where you need us in the most cost and time effective manner. Your deadlines and needs are our priority.

What sets us apart is our unique ability to understand how to provide information that is useful at every level within an organization, in clear and concise terms. Our customers tell us that by using our services they have increased productivity, lowered energy and operating costs, improved worker output and satisfaction and increased company profitability.

Heat Treatment Consultancy – MTS India

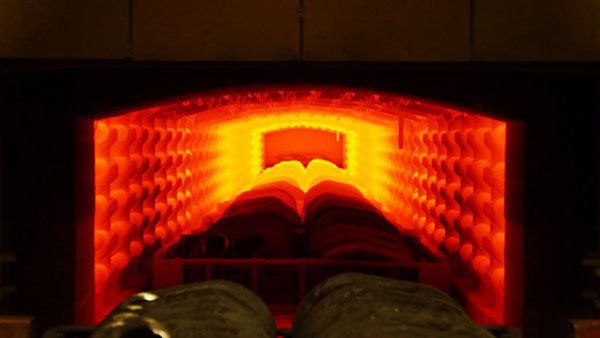

When it comes to achieving optimal material performance, heat treatment plays a critical role. From component strength to hardness and microstructural transformation, heat treatment impacts every stage of industrial production. At MTS India, we offer specialized Heat Treatment Consultancy services tailored to meet your technical, operational, and business challenges — delivering solutions that improve product performance, process efficiency, and overall profitability.

Whether you’re facing unexpected failures, inconsistent mechanical properties, or the need to optimize your current heat treatment process, our experts are here to guide you with data-driven insights and proven solutions.

What is Heat Treatment Consultancy?

Heat Treatment Consultancy is a specialized service that supports manufacturers, fabricators, and material engineers in selecting, validating, and optimizing heat treatment processes. It ensures that materials meet required mechanical, structural, and metallurgical properties through controlled thermal cycles like annealing, quenching, tempering, carburizing, nitriding, and solutionizing.

MTS India provides a strategic combination of metallurgical expertise, process engineering, and forensic investigation to resolve heat treatment-related issues and improve production efficiency.

Why Choose MTS India for Heat Treatment Consultancy?

At MTS India, our consultants are industry veterans with deep knowledge of materials science, thermal processing, and failure analysis. We understand that each industry has unique requirements — from automotive parts needing precise hardness to aerospace alloys demanding microstructural stability.

🔍 Rapid and Reliable Support

We offer rapid response Heat Treatment Consultancy services, ensuring our experts are available on-site or remotely when and where you need them — with minimal downtime and cost impact.

💡 Practical, Actionable Guidance

What sets us apart is our ability to translate complex metallurgical analysis into clear, actionable solutions for your engineers, operators, and decision-makers.

⚙️ Industrial Forensics Approach

We apply our proven industrial forensic methodology to every project — from material selection to process optimization and failure root cause analysis.

Our Heat Treatment Consultancy Services

MTS India’s Heat Treatment Consultancy is structured to address multiple facets of thermal processing, quality assurance, and problem-solving. Our services include:

✅ Process Design and Optimization

We help you design heat treatment cycles tailored to your component geometry, material grade, and application. This includes:

- Choosing the right thermal process (annealing, hardening, tempering, etc.)

- Defining temperature profiles, soak times, and cooling methods

- Minimizing distortion, residual stress, and grain growth

✅ Problem Diagnosis and Root Cause Analysis

Experiencing cracking, warping, surface decarburization, or inconsistent hardness? Our consultants will:

- Investigate process flaws

- Perform metallurgical failure analysis

- Identify incorrect heat treatment practices

- Recommend corrective and preventive actions

✅ Heat Treatment Validation

We verify that your heat treatment processes consistently achieve desired material properties through:

- Sample testing and microstructure evaluation

- Hardness mapping and tensile testing

- Case depth and surface quality assessment

✅ Supplier Evaluation and Auditing

Need to evaluate an external heat treater? We conduct audits to ensure that your suppliers meet standards in terms of:

- Equipment capability

- Process control and documentation

- Material traceability

- Quality assurance systems

✅ Cost and Energy Optimization

Our Heat Treatment Consultancy also focuses on operational improvement, helping you:

- Reduce energy consumption

- Minimize cycle time and scrap rate

- Improve furnace efficiency and uptime

- Lower overall heat treatment cost per part

Industries We Serve

Heat treatment requirements vary significantly across industries. At MTS India, we customize our consultancy to suit your sector-specific needs:

- Automotive – Case hardening, induction hardening, shot peening review

- Aerospace – Precipitation hardening, stress relieving, microstructural control

- Oil & Gas – Quenching and tempering for sour service steels

- Tool & Die – Vacuum heat treatment, tempering cycles for tool steels

- Power Generation – Creep resistance and stress relief treatment validation

- Construction & Heavy Engineering – Weld joint normalization and heat-affected zone management

- Medical Device Manufacturing – Bio-compatible alloy treatment

- Defense and Railways – Precision heat treatment for impact-critical components

Real-World Impact of Our Heat Treatment Consultancy

Our clients have experienced significant improvements by engaging MTS India’s Heat Treatment Consultancy:

- ✅ Improved Yield and Hardness Uniformity

Identified inconsistencies in furnace temperature profiles and redesigned thermal cycles to achieve stable hardness across batches. - ✅ Reduction in Crack Formation

Diagnosed improper quenching mediums and suggested process changes, leading to a 90% reduction in component rejections. - ✅ Energy and Cost Savings

Recommended furnace re-calibration and optimized batch loading schedules, saving over 15% in energy consumption per cycle. - ✅ Audit Readiness and Certification

Prepared clients for NADCAP and ISO audits by streamlining documentation and implementing process control systems.

Deliverables You Can Expect

When you engage MTS India for Heat Treatment Consultancy, you receive:

- On-site or remote expert consultation

- Detailed process evaluations

- Root cause analysis reports

- Metallurgical testing and microstructural validation

- Corrective and preventive action recommendations (CAPA)

- Training for staff on heat treatment best practices

- Ongoing support for process monitoring and improvements

How Our Process Works

- Initial Consultation

We gather information on the problem or improvement area, including part drawings, material specifications, and process history. - Site Visit or Sample Review

Our consultants inspect the heat treatment facility or evaluate representative samples for lab testing. - Technical Analysis

Using metallurgical tools such as microstructure analysis, hardness testing, and SEM, we assess the quality and consistency of the heat-treated parts. - Reporting and Recommendations

A detailed report is shared outlining findings, gaps, and practical steps for improvement. - Follow-Up

We offer ongoing support to track improvements, verify results, and train personnel as needed.

FAQs – Heat Treatment Consultancy

Q1. Can MTS help with urgent on-site heat treatment troubleshooting?

Yes. Our team is equipped to respond quickly for on-site investigations, particularly in cases of production disruptions or component failures.

Q2. Do you support audits and certifications?

Absolutely. We prepare clients for NADCAP, ISO 9001, AS9100, and other quality certifications by aligning heat treatment processes to global standards.

Q3. Is this service only for large manufacturing units?

Not at all. We support small, medium, and large enterprises. Whether it’s a small batch issue or a plant-wide process overhaul, we scale accordingly.

Q4. What if we don’t have in-house metallurgical expertise?

No problem. Our consultants act as your extended technical team, providing all necessary guidance, testing, and documentation support.

Contact MTS India – Heat Treatment Consultancy You Can Trust

When your product’s performance depends on precision thermal processing, trust MTS India’s Heat Treatment Consultancy to deliver clarity, consistency, and control. From solving metallurgical mysteries to helping you design robust processes, we stand by your side every step of the way.

📞 Call us at +91 98417 07777

📧 Email: info@mts-india.in

🌐 Website: https://mts-india.in/

MTS India – Engineering Performance Through Heat Treatment Expertise.

Popular Search : Metallurgical Testing Laboratory Services | Failure Analysis and Metallurgical Testing Company | Best Heat Treatment Services Coimbatore Tamil Nadu | Heat Treatment Service Provider | Heat Treatment Services in Mumbai | Heat Treatment Service Malaysia | MTS-India