Positive Material Identification (PMI) Testing: A Practical Approach

1. The PMI Process in Action

PMI testing is essential for guaranteeing the safety and quality of materials. Let’s go over the necessary procedural measures:

1.Sample Collection: From parts, welds, or raw materials, samples are taken during production or maintenance. These samples are representative of the content being examined.

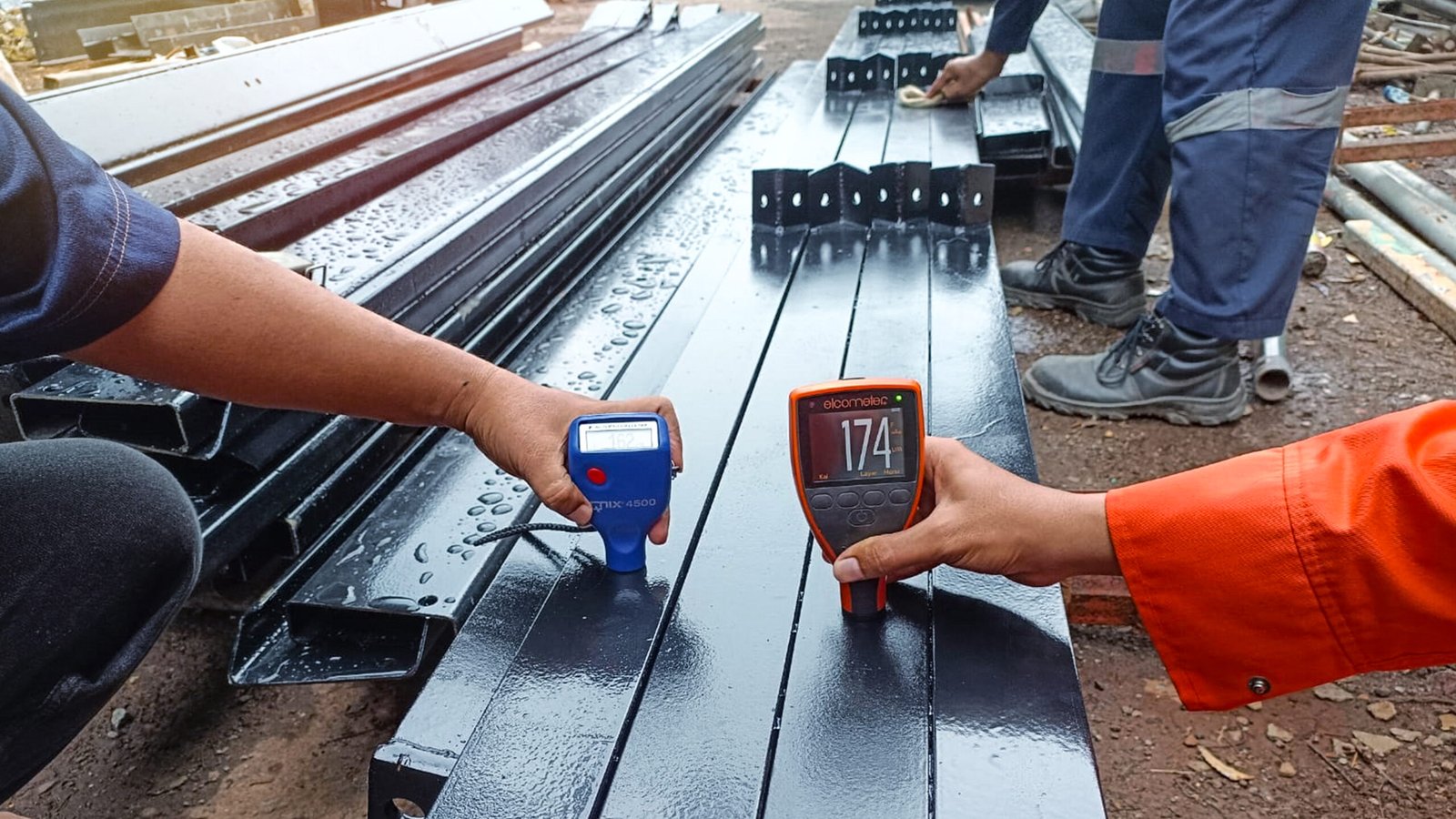

2.Portable XRF Examination: The workhorse of PMI testing is the handheld XRF analyzer from the NITON XL2 800 Series. It works well, is portable, and yields results quickly. This is how it operates:

- Excitation: X-rays are emitted onto the sample surface by the XRF cannon.

- Elemental Emission: Upon impact, the sample emits distinctive X-rays from the atoms.

- Detection: By capturing these released X-rays, the analyzer determines which elements are there.

- Quantification: The concentration of each element is correlated with the X-ray intensity.

3.Quick Results: The material grade and composition are displayed by the PMI pistol in a matter of seconds. If the material satisfies the required specifications, technicians can confirm this.

2. Real-World Applications

Not only is PMI testing theoretical, but it is also practically required in a number of industries:

1.Building and Infrastructure

- Confirming the steel grades used in structural elements.

- guaranteeing the appropriate alloy for bridges and pipes.

2.Oil and Gas

- Verifying the utilization of materials resistant to corrosion in offshore platforms.

- avoiding confusion with important parts like flanges and valves.

3.Automobile and aerospace

- Checking the material integrity of parts used in airplanes.

- ensuring that vehicle parts made of lightweight alloys adhere to standards.

3. Difficulties and Optimal Methods

- Surface Readying: To prevent contamination, ensure the sample surface is thoroughly cleaned and prepped.

- Calibration: To ensure accuracy, calibrate the XRF analyzer on a regular basis.

- Alloy Libraries: For rapid identification, use preloaded alloy libraries.

- Documentation: Keep track of findings and ensure traceability.

4. Beyond Conformance: Dependability and Safety

Keep in mind that PMI testing involves more than just checking boxes. It has to do with dependability, safety, and averting disastrous malfunctions. The correct material is important for any type of structure, be it an airplane wing, pipeline, or pressure vessel.

Count on MTS-India to provide precise PMI readings. Not only are we examining components, but we are also guaranteeing comfort.