Process of Metallography Microstructure & Analysis to Determine Product Viability

The science that deals with the study of microstructure of an element is known as metallography microstructure and analysis. With this analysis, one is able to determine whether the metal has been processed correctly. Then the expert can determine the durability and reliability of the finished product and why the product failed.

For analyzing the element, there is a process for preparing the metallography sample preparation, and the steps are described below for your better understanding.

-

Sectioning & Cutting

Proper consideration is done before selecting the sample for examining it under the microscope, as it will represent the material that is to be studied. If a product has failed and a microstructural analysis is to be done of that product, then the sample will be selected from the region, which will yield more information.

The chosen sample must be free from any form of distortion, deformation, and burning. The sample is cut by means of a hacksaw or mechanical cut-off; the most widely used method is abrasive cutting.

-

Mounting

The sample is mounted as it is a convenient means to handle a small sample, is awkward, and provides proper sample orientation. There are two techniques of mounting hot compressing and cold mounting. Depending upon the type and number of samples, the process is determined.

-

Grinding

With the help of an abrasive belt, the surface of the metal is made flat. The machines used are equipped with coolant so as to wash out the abraded particles from the belt. During the process, the sharp edges are beveled so that the mounted sample doesn’t damage the grinding belt or paper.

-

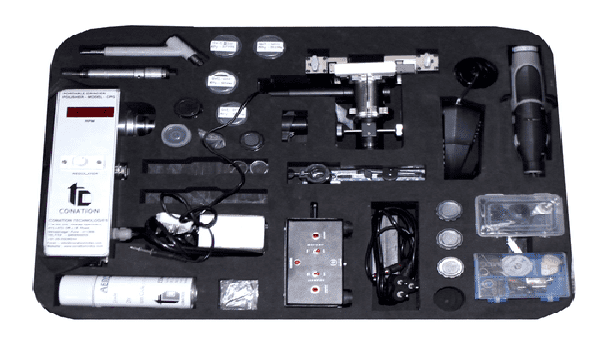

Polishing

This is one of the significant stages in the preparation of the sample for testing. Some chemicals are used to polish the surface of the piece. Then the final polishing is done through a mechanical process to prepare the sample for metallography microstructure and analysis.

-

Hardness testing

To distinguish between different material hardeness testing is essential and improve the technology for testing the material. With the assistance of this test, one can determine characteristics of the element that is essential to use the material in the industries. With the help of this test, the expert comes to know how much mechanical resistance the material has and whether it is suitable for their finished product.

By following the above process, the metallography report is obtained, going through which the engineer or the expert is able to analyze properties of the element and take the decision accordingly, which helps them improve their product.

We learn a great deal about the element’s composition, identity, and thermomechanical history through metallography. An expert will be able to glean all the information considering all aspects and observe the microstructure under a suitable magnification.

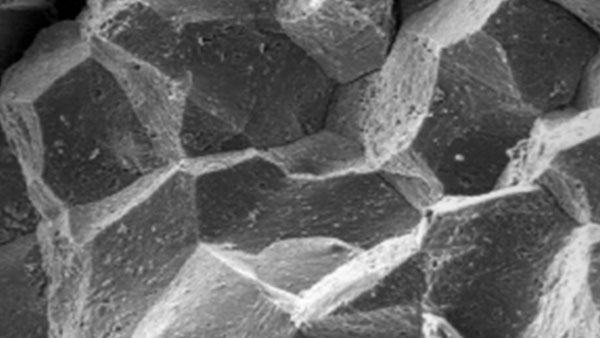

While conducting the microstructure examination, the expert will classify the observation in terms of color, grain size, shape, size, distribution, and segregation effect.

-

Color

If it is in an unetched state, then it is a valuable indicator determining the element is a copper-based alloy. A pure copper will show pinky-red and will undergo gradation in tone towards yellow; then, the zinc content has increased by 40%. Similarly, different alloys will exhibit different colors depending upon their microstructure composition.

-

Grain Shape

Grains of regular and uniform shape is termed as equiaxed or polyhedral, and also the grain size may be referred to as coarse, which is smaller than 1mm and invisible to naked eyes, or fine size, which is more than 1mm.

The size indicates the cooling rate of the metal or the annealing temperature for the element. In deformed metals, the grains are elongated along the direction of the work, and it can exhibit strain bands on etching as direct evidence of deformation.

-

Segregation

Distinction etching on the primary grain will indicate the coring of the solute. Cast alloys with a wide range of melting will show coring, revealing the fir-tree structure in the initially solidified phase. The structural skeleton will have interdimeric sponginess and porosity. Some alloys can also exhibit spherical core.

-

Second Phase

It usually appears in a duplex structure with an intimate design of primary and secondary phases formed due to eutectic reaction, separating the saturated solid solution by continuous cooling or isothermal aging treatment. These structures exhibit various morphologies, which include plate-like or needle-like shapes. Sometimes they also appear as a colony structure under the microscope.

-

Porosity

In a microstructure, a void may appear, and they are usually a central cavity due to primary or secondary pipes. Gas usually occurs as blow holes or cavities which close up during the working.

So, by understanding the microstructures and documenting their observations, the parties involved in manufacturing the product will be able to determine the product’s reliability and durability.

With the help of s, the parties will also be able to decide on the standards that need to be maintained regarding the material used to produce the finished products.